98% of the target product: scientists have developed new methods for synthesizing europium sulfate

14 June 2022 г.

Many compounds of the rare earth metal, europium, have luminescent, catalytic, and magnetic properties. For example, europium sulfate is able to intensively fluoresce, even if it is irradiated with a small amount of ultraviolet light. This compound can be used to manufacture modern luminophores, in particular luminescent pigments, which are capable of glowing for a long time. The existing methods for producing europium sulfate are characterized by such disadvantages as the need for strict temperature control, duration of the process, and low amount of the target product at the output.

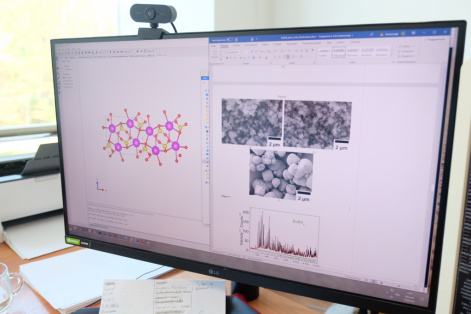

A team of researchers from Russia and Germany, including scientists from the Federal Research Center "KSC SB RAS", developed two efficient methods for synthesizing europium sulfate in the form of powders. Stable compounds of europium sulfide were used as starting materials. In both methods, the yield of the target product is 98–99%.

In the first method, to obtain europium sulfate, the researchers added a solution of sulfuric acid to europium sulfide. With the reaction completed, the precipitate is separated from the liquid, washed, filtered and dried. The reaction takes about 30 minutes. To reduce the time, the scientists decided to conduct it in an ultrasonic bath. Under the influence of ultrasonic vibrations, the reaction proceeds much faster and takes no more than two minutes.

In the second developed method, the synthesis was carried out in two stages. First, europium sulfide was dispersed in distilled water and dissolved in concentrated hydrochloric acid. Then, sulfuric acid was added to the solution, resulting in a precipitate, a white powder of europium sulfate.

“The demand for this work is associated with the development of efficient, relatively simple and scalable methods for obtaining polyfunctional materials. In our study, we obtained the value of the band gap of europium sulfate, which is almost three times larger than that of europium sulfide. This allows sulfate to be used as an optically transparent material, while europium sulfide is actually black. Our team obtained europium sulfate in two independent ways: direct interaction with concentrated sulfuric acid and through an intermediate product, namely, europium chloride. Such options for synthesis affect the reaction rate and concentration of sulfuric acid required for the complete conversion of sulfide to europium sulfate. The presented methods make it possible to obtain a product of high purity in a fairly short time. This is due to the absence of kinetic obstacles in the reduction of europium ions, which are observed in all other methods. Complete processing of the starting compound into the target product ensures its high yield of 98–99%. Minor losses are associated with filtration. The data obtained are of fundamental importance and can be useful for dealing with materials related to the divalent compound of europium,” said Alexander Oreshonkov, Candidate of Physical and Mathematical Sciences, Researcher at the L.V. Kirensky Institute of Physics FRC KSC SB RAS.

Share: