Krasnoyarsk scientists proposed a more technologically advanced and cheaper method for producing durable batteries

18 February 2020 г.

Conventional batteries produce electrical energy as a result of chemical reactions. Betavoltaic sources of energy, nuclear batteries, produce energy owing to the decay of radioactive isotopes. One of the “generators” used in such batteries is an isotope of nickel. Its half-life is as long as one hundred years, which makes the battery on its basis durable. In this case, the beta radiation of the isotope is low energy one, and thus, does not pose a risk to human health. The battery shell itself is enough to guarantee the protection of a living organism from the penetration of radioactive decay particles.

However, creating a nuclear battery is not so easy. In addition to the high price for the nickel isotope, the method of applying it to a substrate which is the basis of the battery, remains challenging. Here, electrochemical and magnetron coating methods are known. However, side processes during the electrochemical deposition of nickel on the surface of semiconductor substrates can cause a significant deterioration in their quality and reduce the battery power, while magnetron sputtering requires sophisticated and expensive equipment.

Scientists of the Federal Research Center "Krasnoyarsk Science Center SB RAS" together with colleagues from the M.F. Reshetnev Siberian State University of Science and Technology and Siberian Federal University suggested using a chemical method to produce nuclear batteries based on the reduction of nickel ions in solution. This will make the process of their production much easier, faster and cheaper.

The chemical method has been known for a long time, but no one has yet tried to use it to create nuclear batteries based on the nickel isotope. Moreover, scientists proposed to use as a substrate a conventional aluminum foil instead of silicon and this foil should be coated with the nickel isotope acting as an energy generator. The nickel coating on aluminum foil has a much larger area for a larger amount of ions to get attached, and accordingly, the amount of energy used increases. In addition, the foil proves to be technologically more convenient: it is easy to process and cover with metal, while it is very easy for us to return the isotope to its original form. Aluminum can be dissolved in alkali, while the expensive isotope deposited on its surface will not be lost. If necessary, this property allows "remaking" low-quality samples.

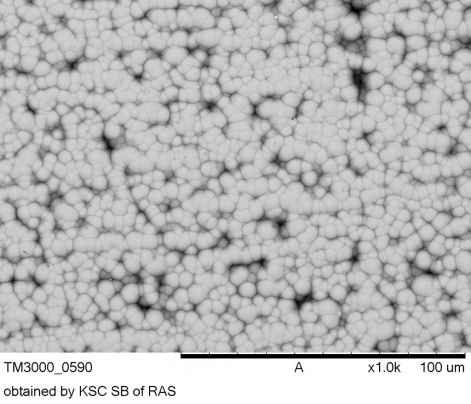

The process itself also appears to be quite simple. A solution with the nickel isotope is poured into a heat-resistant glass. Small samples of foil are placed in the solution and boiled at a temperature of about one hundred degrees. As a result, a layer of the reduced metal is deposited on the aluminum foil substrate. The main advantage of this method is that it can be carried out under normal conditions, without using expensive equipment. To begin with, the researchers tested this method on non-radioactive, stable nickel isotopes. Since radioactive and non-radioactive nickel atoms have the same chemical properties, their behavior would also be identical. This allows us to apply this method to radioactive nickel particles with the same result, but in conditions that are safer for researchers.

“This method has not yet been applied for such purposes. But we decided to use it for testing the application of radiating coatings. There were some fears that with this method of electrolytic coating, a small phosphorus admixture is deposited together with nickel onto a substrate. But we showed that the addition of phosphorus does not harm the coating, but rather strengthens it and does not affect the desired properties. This method of coating is promising for producing nuclear batteries which can work for about a hundred years without additional recharging. Such batteries can be used in various industries, including military and space applications. This technology is especially relevant for medicine. Now people constantly wearing pacemakers keep a battery bag with them as an energy source, which is highly inconvenient. The nuclear battery is capable of having the size at which it can even be sewn into the human body, ” says Natalya Evsevskaya, a post-graduate student, junior research associate at the Institute of Chemistry and Chemical Technology of the Krasnoyarsk Science Center SB RAS.

This work was performed under the financial support of the Federal Target Program.

Share: