Nanoparticles will increase ore mining productivity

13 November 2019 г.

Processing metal ores is a complex and time-consuming process. Sometimes the content of the desired element in the rock does not exceed one percent. To obtain valuable compounds, various mineral processing methods are of use, one of the being froth flotation. The technology consists in the following. When compressed air is passed through a mixture of the crushed ore with water, there occurs the formation of tiny bubbles. Under certain conditions, mineral particles attach to them and float to the surface in the form of a froth. For example, in lead mining, it is lead sulfide which is attached to air bubbles. Three quarters of the resulting froth will consist of a beneficial compound.

With the depletion of mineral reserves, more and more refractory ores are introduced into ore mining. Scientists are faced with the task of increasing the productivity of their extraction, processing and beneficiation. In particular, to make froth flotation more efficient, xanthogenates - derivatives of carbonic acid, soluble salts - are involved in the process. In a solution, such salts together with metals form nanoparticles of a new insoluble substance. The nanoparticles increase the ability of the mineral to adhere to air bubbles and enhance the formation of the beneficiation froth.

The Krasnoyarsk scientists determined under what conditions the froth flotation is best suited for dressing of lead-containing ores. This turned out to be largely dependent on the ratio of lead nitrate and potassium salt. In the flotation process, when lead nitrate is added to potassium salt, there occurs an exchange reaction - lead and potassium “exchange their places”. As a result, nanoparticles of the new insoluble compound are formed from salt and lead. Moreover, if lead is in excess, small nanoparticles with a diameter of about fifty nanometers are formed in the solution. With the reactant ratio of 2 to 1, the particles formed are slightly larger, but still stable. With the decreasing amount of lead and increasing potassium salt, the nanoparticles break up with a certain acidity of the medium. This is due to the fact is that with an equal ratio of the reagents in the froth, an unstable lead monoxanthogenate compound is formed, which loses its weight as soon as at a temperature of 70 degrees Celsius. With other ratios of reagents, lead xanthogenate is formed, which begins to decompose only at a temperature of 120-130 degrees Celsius.

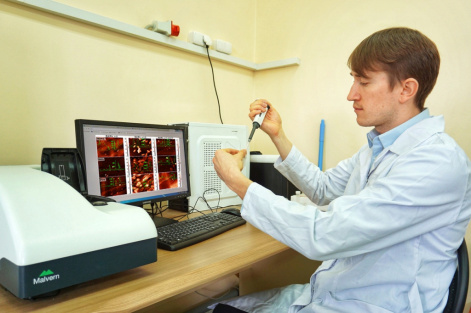

“We were interested in the formation of lead xanthogenate nanoparticles during the froth flotation, since no one had previously deliberately investigated this process. We studied why and how they form, how they interact with acidic and alkaline solutions. Knowing the properties of the particles and the conditions of their formation, we can use them for specific needs, for example, not only in the flotation process, but also for the creation of composite materials, ” said Sergey Vorobyev, Candidate of Chemical Sciences, research associate at the Institute of Chemistry and Chemical Technology of the Krasnoyarsk Science Center SB RAS.

The study was supported by the Russian Science Foundation.

Share: