Siberian scientists have learnt to detect and eliminate deformations in industrial ceramics

13 August 2019 г.

Barium titanate is a crystalline material with high dielectric permittivity, which determines its electric insulation properties. It is applied to create industrial ceramics which is used in electronics and radio-engineering as an element of capacitors, generator sensors, posistors, electric acoustic devices and microphones capable of working with ultra-sound; the material is also used for insulating films in electronic devices.

For the production of ceramics, crystalline powder of barium titanate is pressed into pellets. However, in this form the material has one considerable disadvantage. After compression it forms deformations which considerably change its dielectric permittivity. The annealing of ceramics at a constant temperature for some period of time allows one to return it to its initial state when the pressure in the material “is levelled” and the properties are not destroyed. However, in the process of thermal treatment it is not possible to determine how long the material is to be annealed and until recently, there have not been any simple and quick methods of measuring the residual deformations. Physicists from Krasnoyarsk and Novosibirsk have solved this problem.

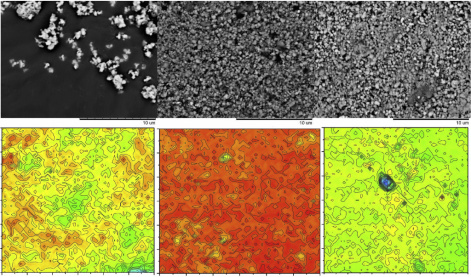

The scientists from the Kirensky Institute of Physics of the Krasnoyarsk Science Center SB RAS and Institute of Automatics and Electrometry SB RAS, Novosibirsk, have developed and tested a method which allows controlling residual deformations of barium titanate microcrystals in ceramics. The deformed areas in the compacted material can be found using spectral mapping. The method allows controlling the quality of the produced ceramics.

In order to detect the changes in the material structure the scientists used Raman scattering spectroscopy. This method is based on changing the frequency of the incident optical radiation upon the interaction with the molecules of a substance. In this case, in the spectrum of the scattered light there appear spectral lines which are absent in the primary light. First, the scientists estimated how light was scattered on the crystalline powder of barium titanate. It allowed them to build a calibration curve, the dependence of the spectral line location on the applied pressure. Further, when comparing the initial image with the Raman scattering spectra of the compacted samples they saw the differences which enabled them to determine the degree of deformation in the samples. With the help of these spectra it is possible to estimate whether the material returned to its initial state or not. The method of Raman scattering allows studying objects of various size and local changes in the structure in small areas of samples.

“Using our method one can successfully measure residual deformation. At present, this is the only existing method and it is not clear whether the residual deformation can be measured using another technique. The method is also applicable to other materials which can be the basis for industrial ceramics and require controlling the residual changes of the inner structure under pressure. In the course of work, our team built calibration curves. Further, for similar estimation it is possible to use our universal calibration for barium titanate materials. This method, instead of repeated annealing, allows one to measure pressure in the process of annealing and based on this, to record deviations,” explains Alexander Krylov, Candidate of Physical and Mathematical Sciences, senior research associate of the Kirensky Institute of Physics KSC SB RAS.

The suggested method can be used to control the quality of the produced ceramics and non-uniformity of its properties caused by the structure deformation, for example, such as, the non-uniformity of acoustic fields in electro-acoustic devices and ultra-acoustic radiators.

The work was supported by the RFBR.

Share: