Siberian scientists have created a polyethylene "body armor" for radar equipment

24 September 2020 г.

Ultra-high molecular weight polyethylene is widely and effectively used in various technical applications and, in particular, in medicine. In fact, this is ordinary polyethylene; the only difference is that the length of its atomic chain is tens of times longer than that of other polymers, which gives it a number of advantages. Such materials can withstand extremely low temperatures, high humidity, corrosive acidic environments and deformation loads. They are characterized by strength, wear resistance and the ability to withstand high shock loads. Despite these properties, the dielectric constant of this polymer is insufficient for it to be used in radar.

Scientists of the Federal Research Center "Krasnoyarsk Science Center of SB RAS" together with colleagues from the G.K.Boreskov Novosibirsk Institute of Catalysis SB RAS synthesized a composite based on polyethylene modified with multiwalled carbon nanotubes. The resulting material has a high dielectric constant and low dielectric losses. At the same time, its wear resistance increased by almost 40% in comparison with the original material.

In the beginning the aim of the study was to increase the dielectric constant of polyethylene, so that it can be used as a coating which is radiotransparent in a given frequency range. To do this, scientists decided to modify the material with nanotubes. To obtain the required effect, the nanoparticles had to be distributed in the material so that they were evenly dispersed and did not come into contact with each other. Otherwise, the properties of polyethylene will deteriorate.

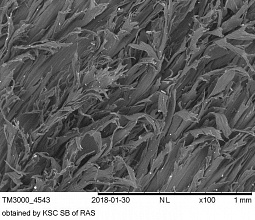

To evenly distribute nanotubes in the material, the scientists mixed the components with a solvent, and the resulting solution was irradiated with ultrasound. After mixing, the scientists removed the solvent and pressed the material. It is this synthesis method which made it possible to arrange nanoparticles evenly and improve the dielectric properties of the composite. In addition, the new polymer has gained another positive feature - its wear resistance has increased by almost 40%. And, according to the scientists, this is not due to the addition of nanoparticles.

This change in the properties of the composite caused ultrasonic radiation, which was used during the synthesis of the material to embed nanotubes into it. As part of the test, scientists also created a polymer under the same conditions, but without nanoparticles. It turned out that it is precisely the ultrasonic effect that changes the structure of the polymer and determines the formation of its structure, which proved to be more wear-resistant.

“Ultra high molecular weight polyethylene was chosen as the basis. It has higher strength than conventional polyethylene and high wear resistance, more than PTFE or Teflon, which are some of the most wear-resistant polymers. Since it has such amazing properties, it was interesting to improve the material for radio electronics using nanotubes. We were expected to increase the dielectric constant and prevent high dielectric losses. Accordingly, the material will also accumulate electrical energy. But the most important thing is that it will transmit electromagnetic waves of the required frequency, and, on the contrary, extinguish others. This is very important for radar equipment, ” says a co-author of the study, Ilya Markevich, an engineer at the Institute of Chemistry and Chemical Technology of KSC SB RAS.

Ultra-high molecular weight polyethylene is applied in many areas. It is used to make covers for skis, snowboards, skating rinks, body armor and helmets, implants for knee and hip joints, and even for such simple household items as cutting boards. Thanks to the new development of Siberian scientists, the use of ultra-high molecular weight polyethylene as a coating for radar equipment has been added to this list; this coating can protect it from impacts, shots of firearms and external climatic influences.

Share: