Russian technologists have studied how hardening pressure affects the parameters of a copper superconductor

29 June 2020 г.

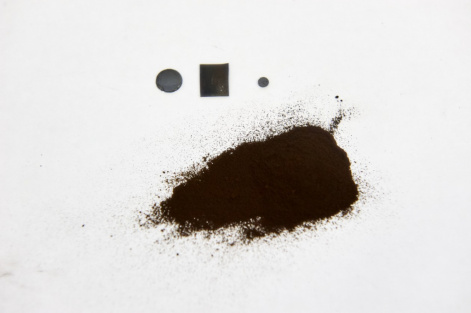

Copper oxide (CuO) nanoparticles have attracted the attention of scientists because of their unusual magnetic properties which can be used to create high-temperature superconductors, electrolytes, and highly sensitive sensors. Copper oxide nanoparticles are a semiconductor with antiferromagnetic ordering, with the magnetic moments of neighboring atoms being compensated by the opposite direction. However, with a decrease in size, such properties as ferromagnetism (magnetic moments are directed in parallel) at room temperature, effect of exchange bias (a feature of the magnetization reversal curve), and change in the temperature of antiferromagnetic ordering begin to appear. The synthesis of copper oxide particles occurs in a plasma chemical reactor with a gas; increasing the pressure in the reactor accelerates the synthesis process and allows adjusting the particle size up to 40 nanometers (which is about 2500 times thinner than human hair). In their work, researchers studied the properties of nanoparticles obtained at different pressures.

“We performed the plasma-chemical synthesis of copper nanoparticles on an arc evaporator. Argon served as a plasma-forming gas, which was supplied to the chamber together with oxygen and formed a shell around the plasma torch. Then, we studied the component composition of the nanoparticles with an electron microscope, and carried out the structural analysis using an X-ray diffractometer, ” says Anatoly Ushakov, a participant of the project on a grant from the Russian Science Foundation, a researcher at the Krasnoyarsk Science Center SB RAS and Siberian Federal University.

Scientists obtained two groups of particles which were synthesized at a pressure of 0.0004 and 0.002 atm. At lower pressures, the size of nanoparticles varied from 15 to 60 nanometers, and their magnetic properties hardly differed from the parameters of the bulk material. In the case of a pressure of 0.02 atmospheres, the sizes ranged from 15 to 45 nanometers, and the parameters of copper oxide changed greatly. It had magnetic hardness, that is, it retained its magnetization for a long time, which turned out to be increased. According to the researchers, this was due to the formation of ferromagnetic dendritic (tree-like) shells on the nuclei of nanoparticles synthesized at a higher rate.

In different sectors of industry, different conductive materials with different parameters are needed. In many situations, additional properties may be required, and sometimes one can do without them, simplifying the process of the copper oxide production. Studies by Russian scientists show that the dimensions and properties of an electrical conductor can be influenced by changing the pressure in the reactor.

Source: Press Service of the Russian Science Foundation

Share: